Project Showcase

A selection of precision components manufactured for leading OEMs and defense primes across multiple industries.

Aerospace

AerospaceF-35 Avionics Housing

Titanium 5-axis machined housing for avionics system. Flight-critical component requiring full material traceability, FPI, and CMM inspection per AS9100D.

Medical

MedicalSurgical Robot End Effector

316L stainless micro-machined instrument tips for robotic surgical system. ISO 13485 compliant with full biocompatibility documentation.

Automotive

AutomotiveEV Battery Enclosure

6061 aluminum welded assembly for electric vehicle battery system. 15,000 units per year with JIT delivery and PPAP documentation.

Energy

EnergyGas Turbine Nozzle Ring

Inconel 718 precision machined nozzle ring for gas turbine engine. NADCAP-certified heat treatment and non-destructive testing.

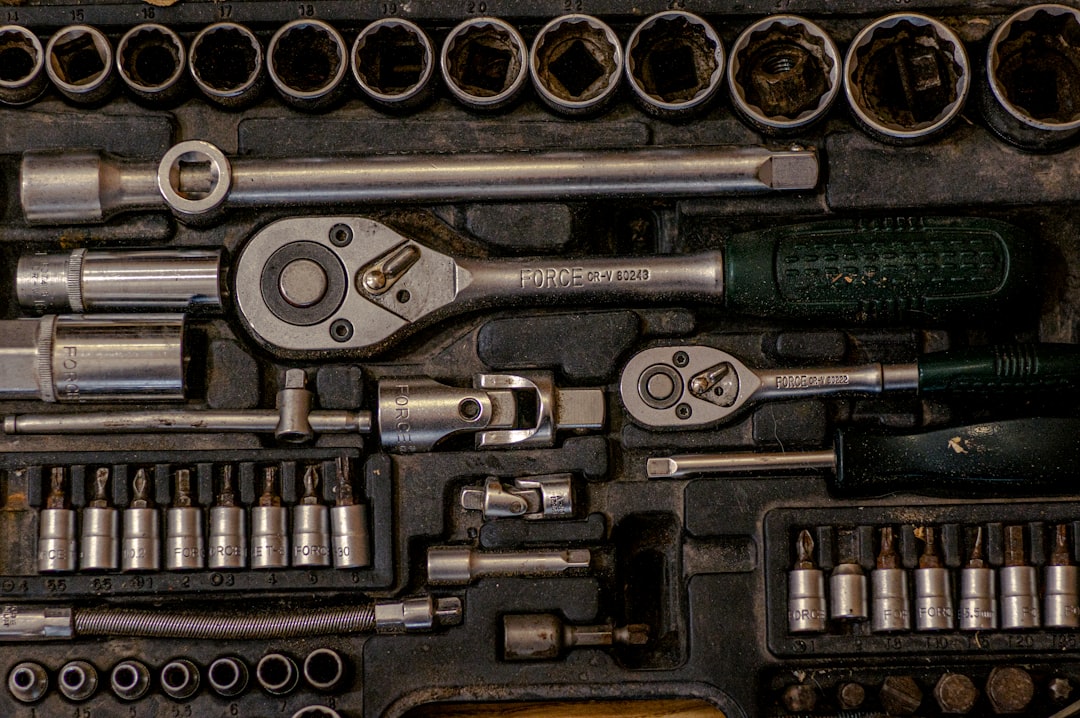

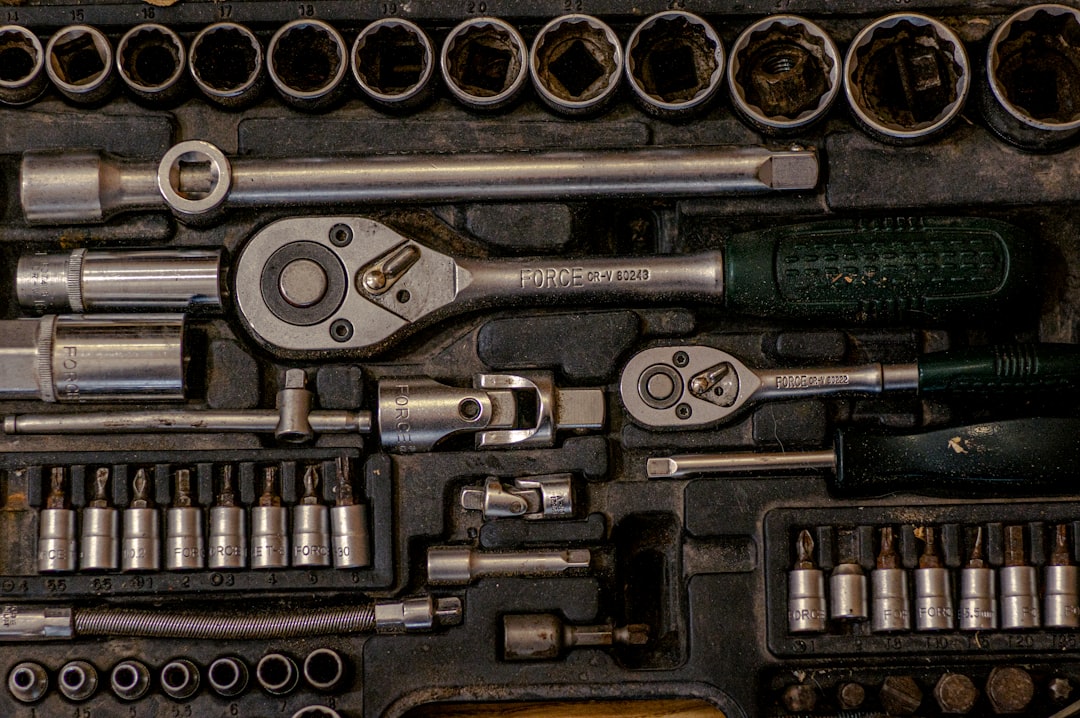

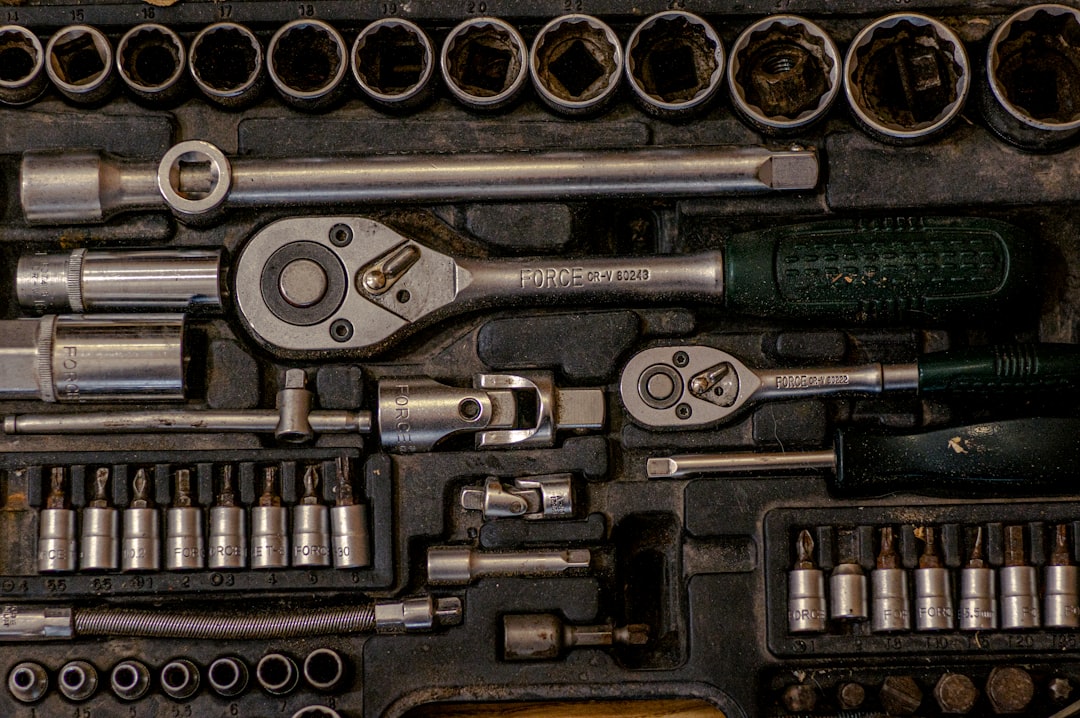

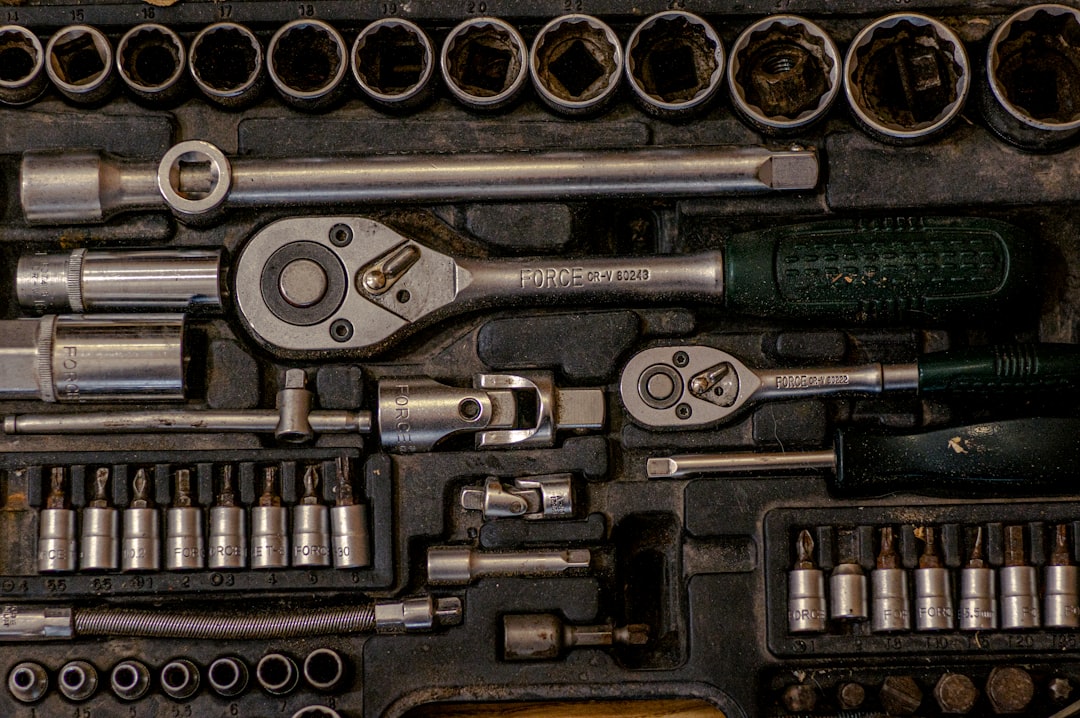

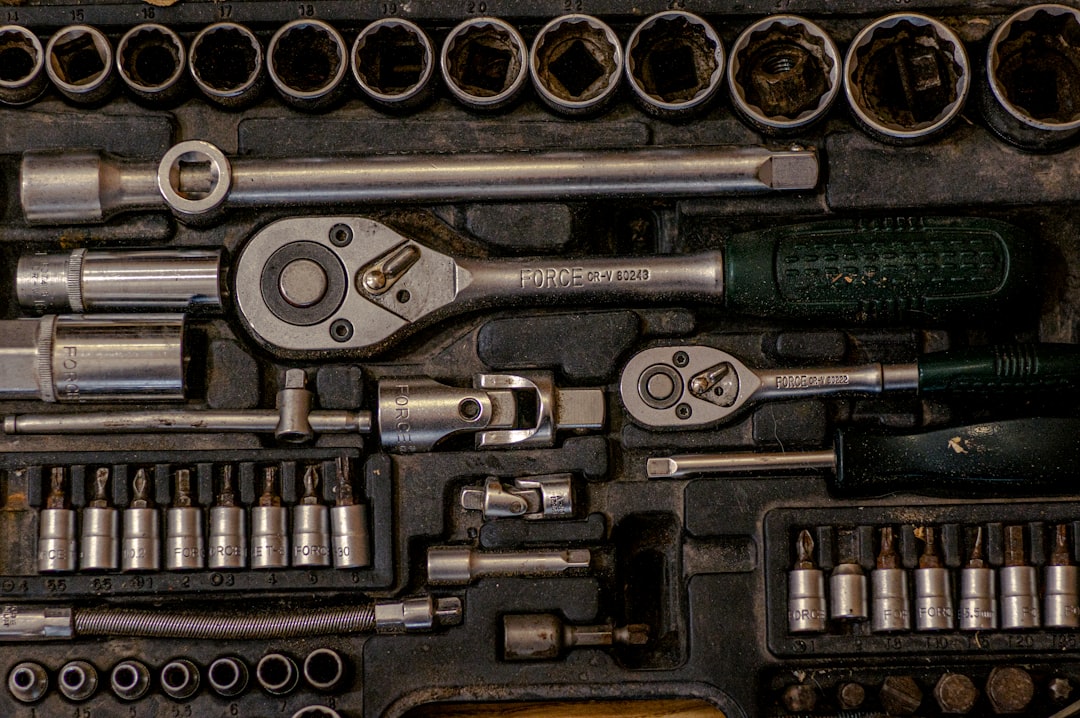

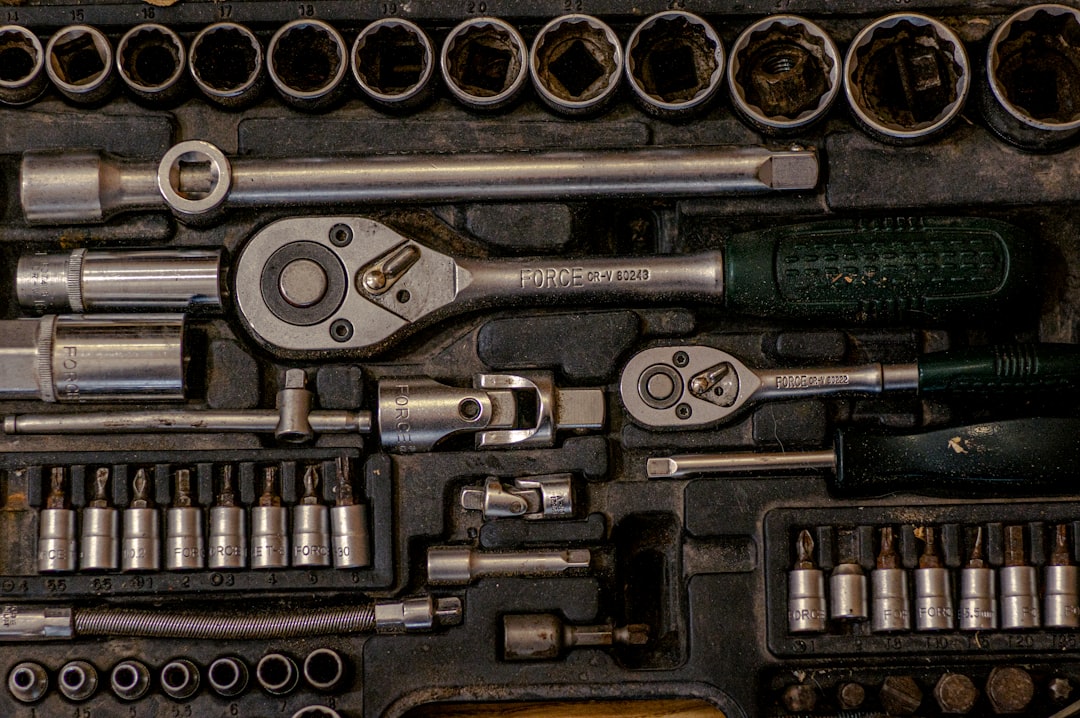

Industrial

IndustrialHydraulic Manifold Block

4140 steel 28-port manifold block with full CMM inspection. Cross-drilled passages with surface finish requirements to 16 Ra.

Aerospace

AerospaceSatellite Antenna Bracket

Aluminum 7075-T6 flight-qualified hardware for satellite antenna system. Full dimensional inspection and material certification per AMS standards.

What Our Clients Say

Apex delivered our flight-critical titanium housings ahead of schedule with zero defects across 200 units. Their AS9100 program is rock solid.

David Kowalski

Senior Procurement Manager

Northline Aerospace Systems

We switched our surgical instrument machining to Apex three years ago. The quality and consistency are exactly what we need for FDA-regulated products.

Dr. Michelle Torres

VP of Engineering

Meridian Medical Technologies

From prototype to 15K annual production, Apex has been our go-to for EV battery enclosures. Their engineering team helped us reduce cost by 18% through DFM.

James Chen

Director of Supply Chain

Volterra Automotive

Your Project Could Be Next

From single prototypes to annual production contracts, we deliver precision parts on time and on spec.