Full-Service Precision Manufacturing

Everything under one roof. From 5-axis CNC machining to clean room assembly, we control every step of the manufacturing process.

CNC Machining

5-axis CNC milling and turning with tolerances to ±0.0005". Aluminum, steel, titanium, Inconel, and exotic alloys.

Key Capabilities

- 5-axis simultaneous milling

- CNC turning up to 24" diameter

- Tolerances to ±0.0005"

- Hard metal machining (Inconel, titanium, tool steels)

- Live tooling and sub-spindle operations

- Lights-out automation capability

Equipment

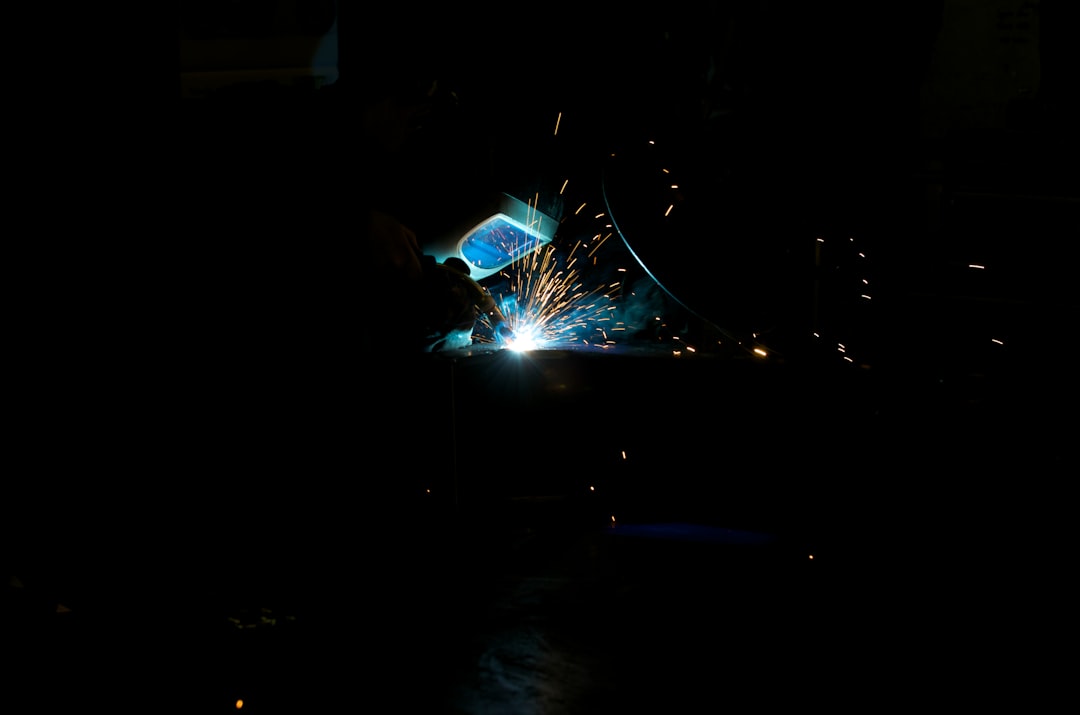

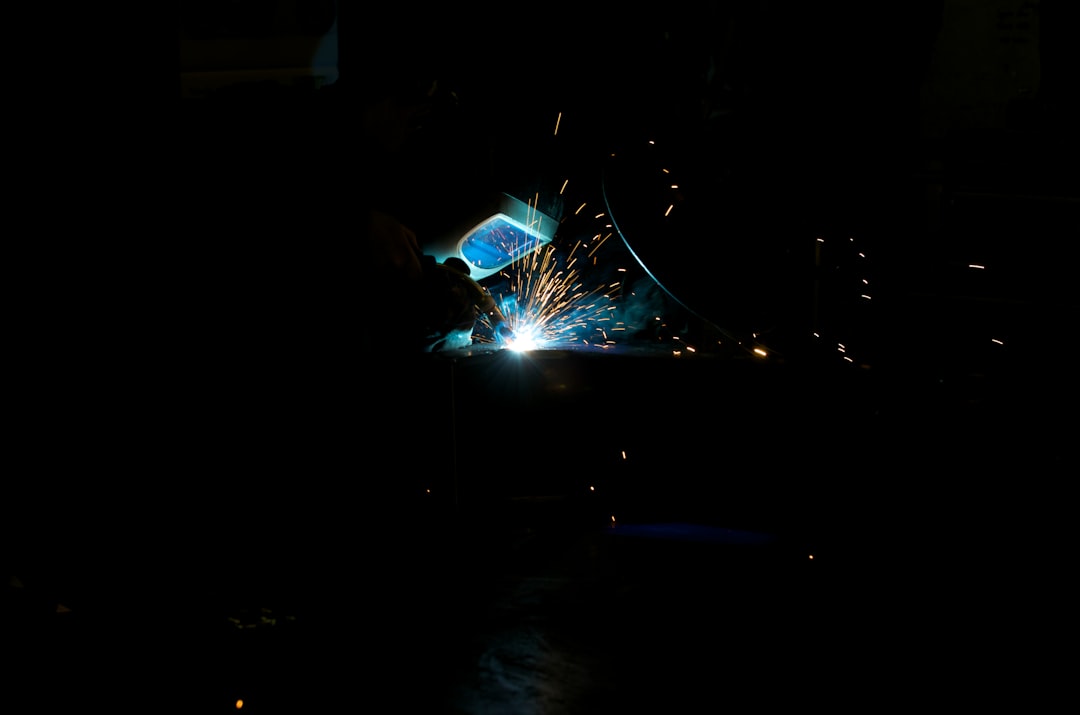

Sheet Metal Fabrication

Laser cutting, press brake forming, welding (TIG, MIG, robotic), and powder coating. Prototype through production volumes.

Key Capabilities

- Fiber laser cutting to 1" steel

- CNC press brake forming to 14' length

- TIG, MIG, and robotic welding

- Spot welding and hardware insertion

- Powder coating and wet paint finishing

- Prototype through 50,000+ unit runs

Equipment

Precision Assembly

Clean room and standard assembly, torque-controlled fastening, functional testing, and sub-assembly integration.

Key Capabilities

- ISO Class 7 clean room assembly

- Torque-controlled fastening with data logging

- Functional and leak testing

- Sub-assembly and full system integration

- Custom fixturing and work holding

- Lot traceability and serialization

Equipment

Additive Manufacturing

Metal and polymer 3D printing for rapid prototyping, tooling, and low-volume production parts.

Key Capabilities

- DMLS metal printing (stainless, titanium, aluminum)

- SLS nylon and polymer printing

- FDM for fixtures, jigs, and prototypes

- Rapid prototyping in 3–5 business days

- Post-processing and finishing

- Design optimization for additive

Equipment

Surface Treatment

Anodizing, plating, passivation, heat treatment, and specialty coatings. In-house and managed vendor network.

Key Capabilities

- Type II and Type III anodizing

- Electroless nickel plating

- Passivation per ASTM A967

- Heat treatment and stress relief

- Chemical film (Alodine) coating

- Managed vendor network for specialty processes

Equipment

Engineering Support

DFM analysis, tolerance review, material selection, CAD/CAM programming, and reverse engineering services.

Key Capabilities

- Design for Manufacturability (DFM) analysis

- Tolerance stack-up review

- Material selection and optimization

- CAD/CAM programming (Mastercam, NX)

- Reverse engineering with 3D scanning

- Value engineering and cost reduction

Equipment

Not Sure Which Process Is Right?

Send us your drawings and our engineering team will recommend the optimal manufacturing approach for your part.