Precision engineering. National scale.

From prototype to production, Apex Manufacturing delivers precision-machined components for the most demanding industries. 185,000 sq ft. 48 CNC machines. 32 years of excellence.

Manufacturing Capabilities

Full-service precision manufacturing under one roof. From raw material to finished, inspected parts.

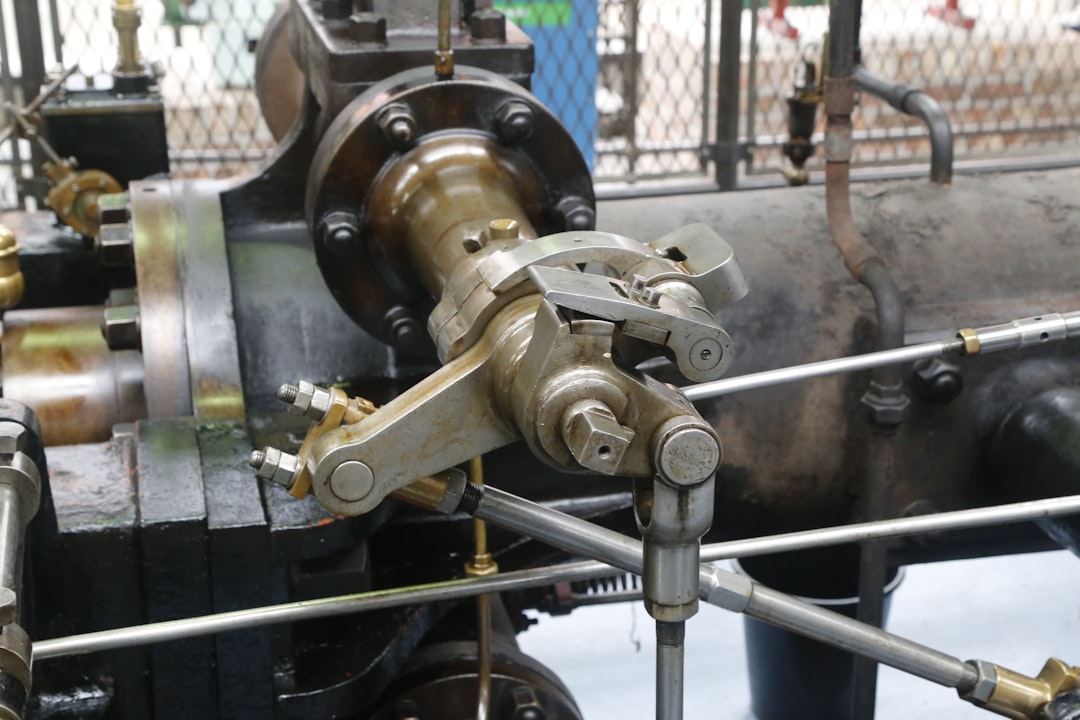

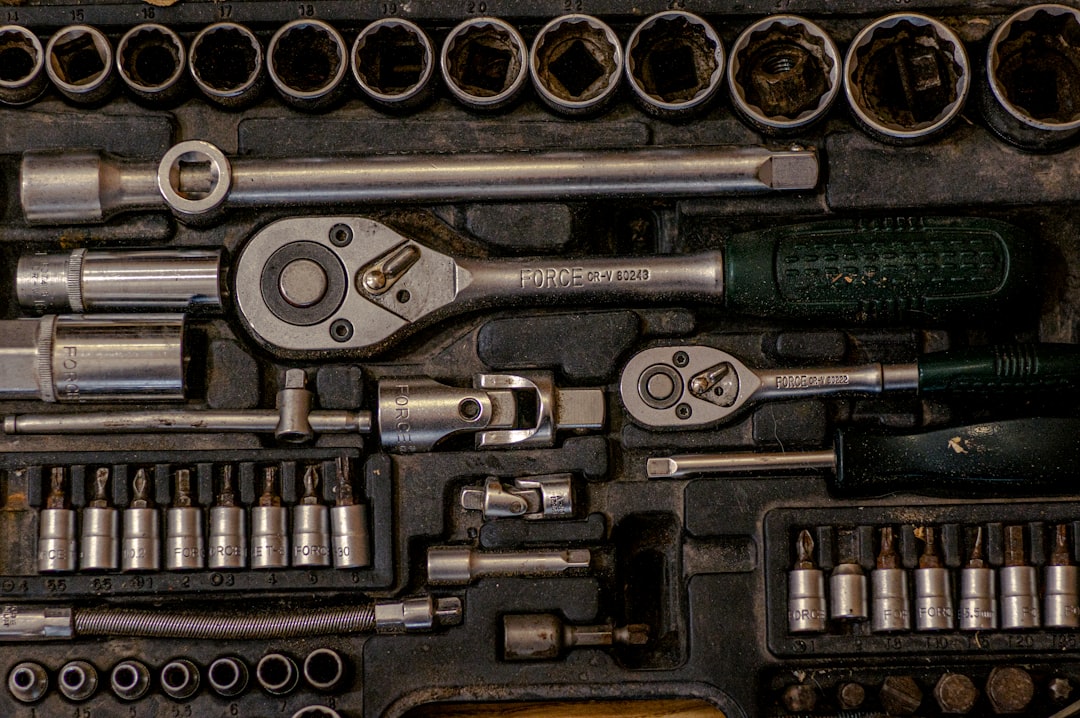

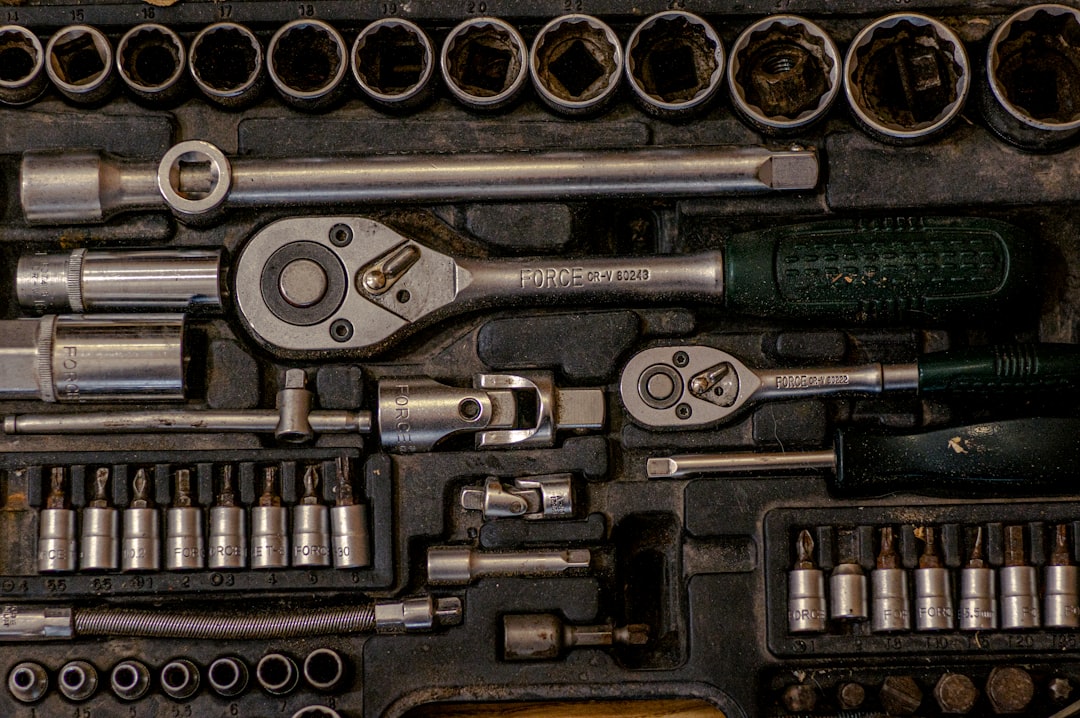

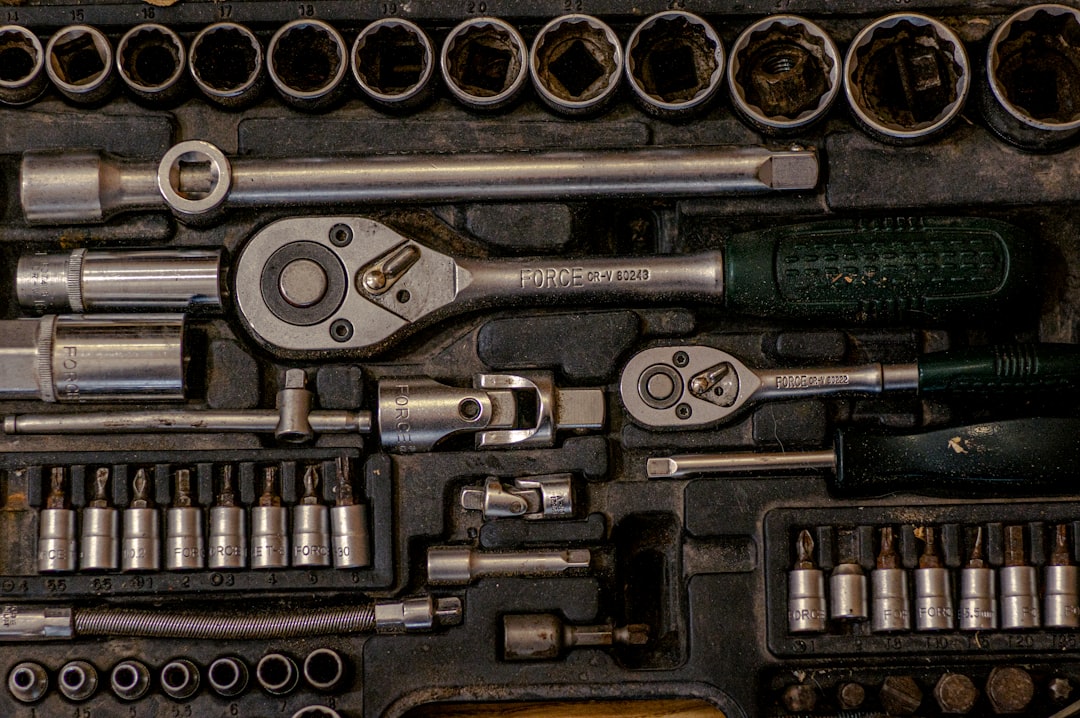

CNC Machining

5-axis CNC milling and turning with tolerances to ±0.0005". Aluminum, steel, titanium, Inconel, and exotic alloys.

Sheet Metal Fabrication

Laser cutting, press brake forming, welding (TIG, MIG, robotic), and powder coating. Prototype through production volumes.

Precision Assembly

Clean room and standard assembly, torque-controlled fastening, functional testing, and sub-assembly integration.

Additive Manufacturing

Metal and polymer 3D printing for rapid prototyping, tooling, and low-volume production parts.

Surface Treatment

Anodizing, plating, passivation, heat treatment, and specialty coatings. In-house and managed vendor network.

Engineering Support

DFM analysis, tolerance review, material selection, CAD/CAM programming, and reverse engineering services.

Sectors We Serve

From flight-critical aerospace to FDA-regulated medical devices, we meet the most stringent quality standards.

Featured Projects

A sample of precision components delivered to industry-leading OEMs and defense primes.

Aerospace

AerospaceF-35 Avionics Housing

Titanium Ti-6Al-4V · ±0.001"

Titanium 5-axis machined housing for avionics system. Flight-critical component requiring full material traceability, FPI, and CMM inspection per AS9100D.

Medical

MedicalSurgical Robot End Effector

316L Stainless Steel · ±0.0005"

316L stainless micro-machined instrument tips for robotic surgical system. ISO 13485 compliant with full biocompatibility documentation.

Automotive

AutomotiveEV Battery Enclosure

6061-T6 Aluminum · ±0.010"

6061 aluminum welded assembly for electric vehicle battery system. 15,000 units per year with JIT delivery and PPAP documentation.

“Apex delivered our flight-critical titanium housings ahead of schedule with zero defects across 200 units. Their AS9100 program is rock solid.”

David Kowalski

Senior Procurement Manager, Northline Aerospace Systems

Ready to Start Your Next Project?

Send us your drawings or specs. We quote within 24 hours and ship nationwide.